rickstrong

New member

Greetings All,

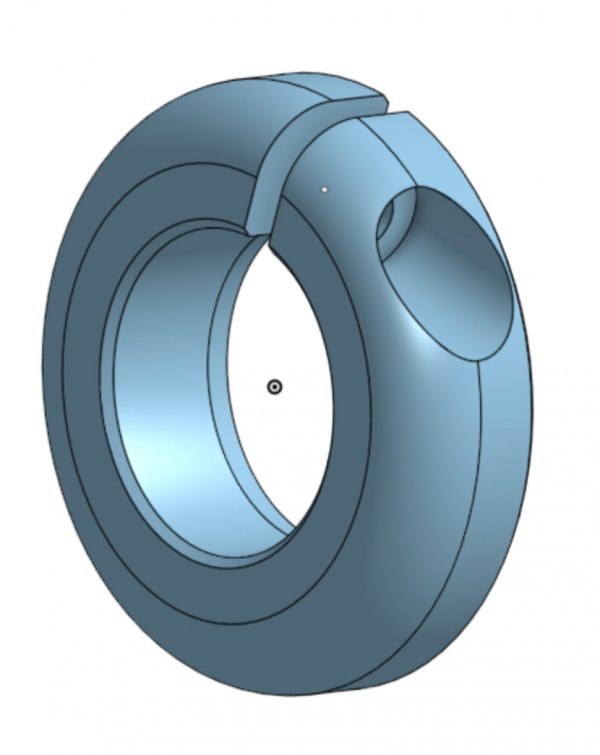

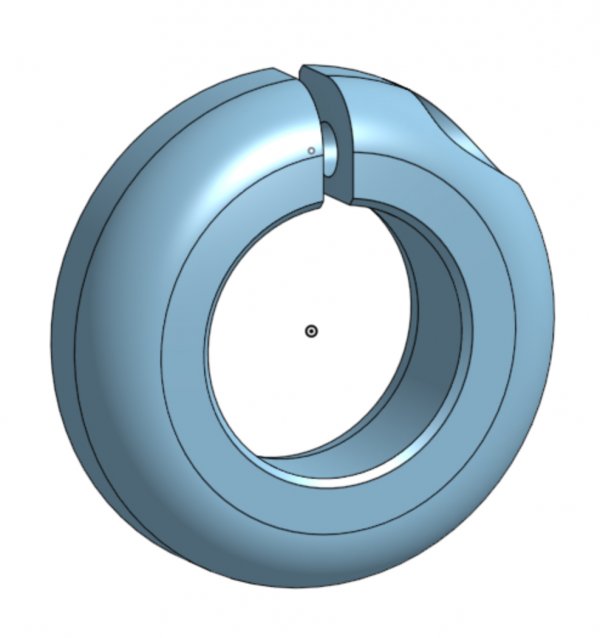

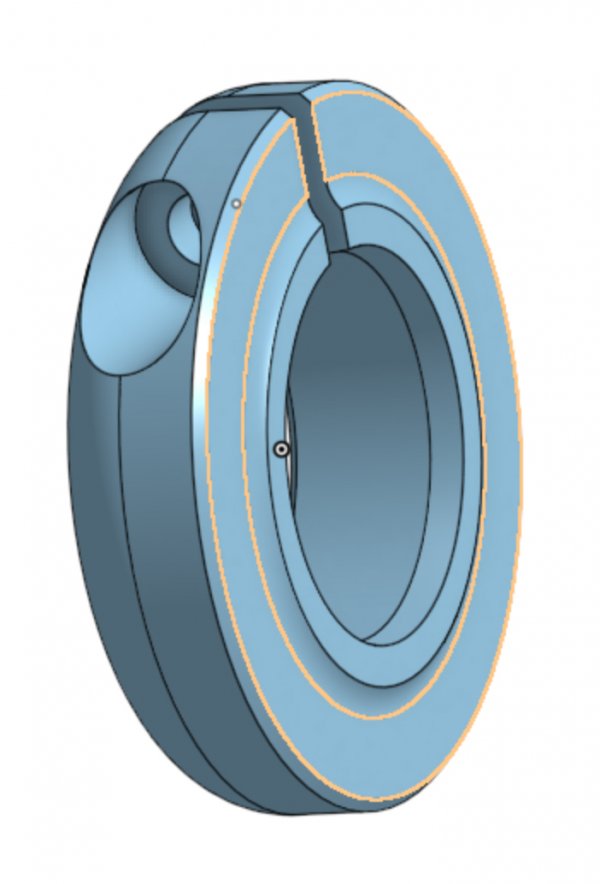

I'm sure this is a familiar theme. I have a 1986 Wicked Fat Chance, and as with many others one of the aluminum bottom bracket spindle collars has cracked. I had seen in a post several years ago that Rody Walter at Groovy Cycle Works sold replacement collars. Unfortunately, this is no longer the case. He suggested that I contact Chris Chance at the new Fat Chance website, and the support folks there suggested that I ask in one of the user groups :-/

Are there any sources of replacement collars or suitable substitutes?

I'm sure this is a familiar theme. I have a 1986 Wicked Fat Chance, and as with many others one of the aluminum bottom bracket spindle collars has cracked. I had seen in a post several years ago that Rody Walter at Groovy Cycle Works sold replacement collars. Unfortunately, this is no longer the case. He suggested that I contact Chris Chance at the new Fat Chance website, and the support folks there suggested that I ask in one of the user groups :-/

Are there any sources of replacement collars or suitable substitutes?