You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

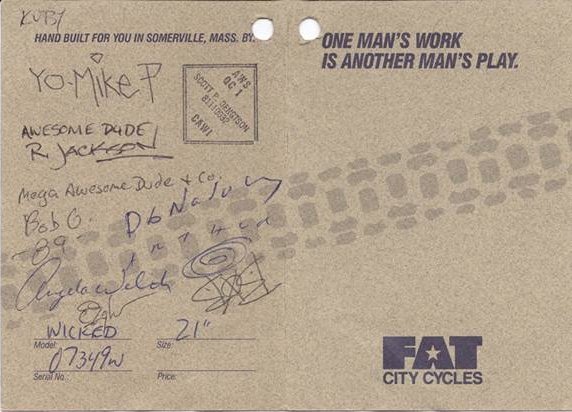

89 Wickedness

- Thread starter Zamfir

- Start date

Minor updates

Finally sorted my cable hanger woes with this bulky looking, but very functional Campy part. Routed the front cable with a v-brake noodle, no flex and finally dialed in.

Also put some nifty Gran Compe rollers front and rear, mainly for looks.

Bike is approaching build nirvana, just need a period seatpost and a m736 FD (I have 736 shifters waiting patiently).

Finally sorted my cable hanger woes with this bulky looking, but very functional Campy part. Routed the front cable with a v-brake noodle, no flex and finally dialed in.

Also put some nifty Gran Compe rollers front and rear, mainly for looks.

Bike is approaching build nirvana, just need a period seatpost and a m736 FD (I have 736 shifters waiting patiently).

Attachments

I-ROBOT

Active member

Yeah, Chris built my fork custom as well, and when I was talking to him about it, he mentioned that all of the old BOI and Yo Eddy forks floating around (and bringing in huge $ on ebay) were not heat treated and that he couldn't convince Chris to spring for that back in the day.

I also recall that the first forks didn't have that teardrop gusset on the back and they broke, so they added it (I think that story was told here, maybe by Scott B?). So when mine didn't come with the gussets (I didn't ask for them either, just told him I wanted a segmented fork with 1990 Wicked Geo) I assumed it was because the modern heat treated steel didn't need it. After all, Chris probable built all of those old forks, so if anyone would know - it's be him!

rmp

Hate to bust your bubble but Chris I had left Fat City and was doing his own deal in Maine before the first Yo Eddy was built. He did weld some box crown forks and he may have done a couple of prototype segmented forks but he would not have done any production forks. All of the Yo and BOI forks were welded by George Reynolds, Dave Blakeney, Sue Kirby, and Patrick. I did a few, but not that many. I believe I welded all of the segmented road forks that came out of Somerville, but some of those could have been done by others.

I was also a strong proponent of heat treating the Yo forks. We did some fatigue testing after some early cracking and that did lead to the tear-drop gusset so Chris decided against it.

Happy Holidays to all

Scott

I'm ecstatic about the front brake feel. The old hanger didn't fit correctly, it would bend down slightly when i'd get on the brake giving it a mushy feel.

Anybody have thoughts about the seat that's currently on the Wicked? I have a Rolls i'm thinking of moving from a different bike, also going to get a period correct seatpost.

Anybody have thoughts about the seat that's currently on the Wicked? I have a Rolls i'm thinking of moving from a different bike, also going to get a period correct seatpost.

jpicard616

New member

I'm not a fan of the saddle, and an old XT seatpost would look really nice!

tvcreative

New member

syncros or american classic on the seatpost is what I have on mine

I like the good ol' flite or turbo on mine

I like the good ol' flite or turbo on mine

wicked

saddles are a personal choice, I tend to use Flites or SDG on many of my bikes. Nice 26.4 seatposts can be hard to find; I like Syncros and Ritchey, also use American Classic, XT and XC pro.

Great color on the bike, in my opinion the black tires are a big improvement over the white. just my 2 cents

saddles are a personal choice, I tend to use Flites or SDG on many of my bikes. Nice 26.4 seatposts can be hard to find; I like Syncros and Ritchey, also use American Classic, XT and XC pro.

Great color on the bike, in my opinion the black tires are a big improvement over the white. just my 2 cents

Thanks for the excellent advice everybody.

I tried a Flight (one of my all time fav saddles) and it just didn't quite look right to my eyes.

Then I moved a Rolls over from a 80's road bike I have stored in the "beer cave". Looks better and it will stay for a little while but now i'm thinking a Turbo or Concor, possibly in suede, might be the saddle.

Seatposts will be a far tougher choice and I will be patient. IRD would be on the top of my list, then I think American Classic. I really love Syncros parts but to me they are too west coast for the Wicked.

I tried a Flight (one of my all time fav saddles) and it just didn't quite look right to my eyes.

Then I moved a Rolls over from a 80's road bike I have stored in the "beer cave". Looks better and it will stay for a little while but now i'm thinking a Turbo or Concor, possibly in suede, might be the saddle.

Seatposts will be a far tougher choice and I will be patient. IRD would be on the top of my list, then I think American Classic. I really love Syncros parts but to me they are too west coast for the Wicked.

nader

New member

Finally sorted my cable hanger woes with this bulky looking, but very functional Campy part. Routed the front cable with a v-brake noodle, no flex and finally dialed in.

is it possible to weld or glue such a v-brake noodle to the stem?

Stems with such role or noodle are unfortunately become rare.

I've had similar thoughts about modifying stems, but for length.

When I originally discussed the fork with Chris I also asked if he could modify the T-bone stem that came on the bike. It was crazy long, like 140cm or so, it had the cable guide hole on the top that would have worked nice. He said it was possible, so i sent it to him with a hand sketch. He called back saying that it wasn't a good idea because it would compromise the strength of the stem and would be cost prohibitive. Then he dug up the cool Salsa I ended up with.

Back on subject. If someone if determined to add a cable guide I would think drilling a small hole though the top, then maybe a larger dia hole only through the top of the stem to support an alloy fitting might be the least invasive. Not sure if it would weaken the stem.

I'm just thinking out loud. Certainly there are others here that would know far better than me.

When I originally discussed the fork with Chris I also asked if he could modify the T-bone stem that came on the bike. It was crazy long, like 140cm or so, it had the cable guide hole on the top that would have worked nice. He said it was possible, so i sent it to him with a hand sketch. He called back saying that it wasn't a good idea because it would compromise the strength of the stem and would be cost prohibitive. Then he dug up the cool Salsa I ended up with.

Back on subject. If someone if determined to add a cable guide I would think drilling a small hole though the top, then maybe a larger dia hole only through the top of the stem to support an alloy fitting might be the least invasive. Not sure if it would weaken the stem.

I'm just thinking out loud. Certainly there are others here that would know far better than me.

I've had similar thoughts about modifying stems, but for length.

When I originally discussed the fork with Chris I also asked if he could modify the T-bone stem that came on the bike. It was crazy long, like 140cm or so, it had the cable guide hole on the top that would have worked nice. He said it was possible, so i sent it to him with a hand sketch. He called back saying that it wasn't a good idea because it would compromise the strength of the stem and would be cost prohibitive. Then he dug up the cool Salsa I ended up with.

Back on subject. If someone if determined to add a cable guide I would think drilling a small hole though the top, then maybe a larger dia hole only through the top of the stem to support an alloy fitting might be the least invasive. Not sure if it would weaken the stem.

I'm just thinking out loud. Certainly there are others here that would know far better than me.

You need a noodle inside once you drill the stem. It does give very good braking and clean cable lines. I have a specialized stem on my wicked w/ the hole and a T bone back up. Thing is, those stems used to come in 120/135/150 length. I even like the hole thru than the roller like the salsa.

clockworkgazz

New member

great resto and a cracking colour- top work.

jonsonneborn

Member

A really nice Wicked Build. Is that powdercoated? Looks nice with the segmented fork.

franktrottajr

Member

Hate to bust your bubble but Chris I had left Fat City and was doing his own deal in Maine before the first Yo Eddy was built. He did weld some box crown forks and he may have done a couple of prototype segmented forks but he would not have done any production forks. All of the Yo and BOI forks were welded by George Reynolds, Dave Blakeney, Sue Kirby, and Patrick. I did a few, but not that many. I believe I welded all of the segmented road forks that came out of Somerville, but some of those could have been done by others.

I was also a strong proponent of heat treating the Yo forks. We did some fatigue testing after some early cracking and that did lead to the tear-drop gusset so Chris decided against it.

Happy Holidays to all

Scott

Hey Scott - Just saw this post, had no idea that A.) Igleheart had left prior to the production segmented forks being welded. And B.) You welded ALL the Road Yo! forks, of which I have ridden several, one of which I am STILL riding. Incredible craftsmanship and AMAZING handling fork. Thanks Scott, and hope life is good. Frank

one piece crank

Member

I love it when people come up with clever solutions using existing parts (ie the V-brake noodle.) Oh yeah and the blue with white tires is stunning.

Actually, BITD re-purposed motorcycle throttle noodles were used all the time - starting with the usual suspects (Breeze, Potts, Fisher, Ritchey) up to production bikes in the late 80's.